Coconut Oil filtering machine Tumbler Swing Sieve Machine

Product description

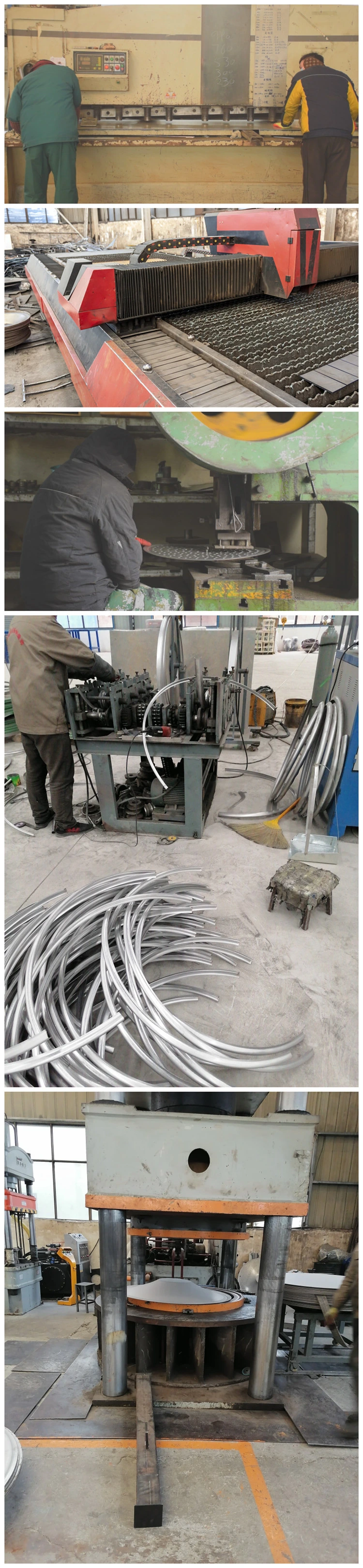

Tumbler sieve machine manufacturing process Cutting plate into strip. then bend and weld the mesh frame.The clamp is made by special purpose machine, the sieve cover is made by pressing machine. The punching plate also is finished by machining .

Cutting plate into strip. then bend and weld the mesh frame.The clamp is made by special purpose machine, the sieve cover is made by pressing machine. The punching plate also is finished by machining . Skilled wedling and grainding bring high qualtiy

Skilled wedling and grainding bring high qualtiy

Basic service

1.Sample material can be free analysis and test in laboratory.

2.24 hours a week online & quick response within 1 hour.

3.Booking hotel and tickets for customers and Free transportation & meals during visit our factory.

4. Standard equipment can deliver within 3-5 working days and delivery time guaranteed.

Customized services

1.Professional R&D team to develop customize as you requirements.

2.Help high-end customers and dealer to develop the local market

3.All packing, shipping and labels can customize as per your requirements.

After-sale services

After customers received the goods,if have any questions or quality problems, Our customer service Dept. will be always available for all kinds of service ways, such as video technical support, drawing guidance, field installation and commssion etc..

Q: How to find suitable model?

moisture, viscous and corrosive etc:

1>Name and feature of the raw material?

2>Aim of using: get rid of impurity, filtration, grading

3>Handling capacity: kg /h, L/h

4>The raw material size: (mesh or mm)

5>How many final materials you want, or how many layer you need?

6>Local power supply (voltage and frequency)

Note: You had better send us the relevant pictures about the details.